Home

Woodworking

Hand Railings

Skirt Boards

Crown Molding

Bidding

Wainscoting

Chair Rail

Interior Doors

Closet Doors

Exterior Doors

Installing Doors

Baseboard

Installing Baseboard

Windows

Install Cabinets

Hand Tools

Power Tools

Blog

Contact

Link Partners

Tool Reviews

About Me

Can't Find Something?

Check The Sitemap

Site Map

Woodworking

Hand Railings

Skirt Boards

Crown Molding

Bidding

Wainscoting

Chair Rail

Interior Doors

Closet Doors

Exterior Doors

Installing Doors

Baseboard

Installing Baseboard

Windows

Install Cabinets

Hand Tools

Power Tools

Blog

Contact

Link Partners

Tool Reviews

About Me

Check The Sitemap

Site Map

[?] Subscribe To This Site

MDF Baseboard

The Benefits of Using MDF Baseboard Materials.Carpenters everywhere always have the same conundrum at the end of a job. That question is how to finish the job and keep it aesthetically pleasing as well as affordable. Where a finishing touch to wood grain paneling is concerned, MDF baseboard finishing material is a great response to that question. This type of baseboard is easy to work with, simple to install and has a great many options after installation.

MDF material is a wood product, but has none of the drawbacks of natural wood base material. The anagram MDF stands for Medium Density Fiberboard. It is comprised of wood particles pressed and glued together under heat and pressure. The result is a resilient material that is easy to cut and work with.

The main benefit of this mdf material is that it has no grain pattern so it does not clash with the grain of the paneling. It also has none of the natural defects that sometimes come with natural wood baseboard materials. I am sure you have run into knotholes and petrified portions of wood at times. This causes a bad cutting experience and is most times hidden in the wood with no exterior evidence.

MDF material does not splinter during sawing either, so you get a smooth cut surface every time. From a standpoint of material cost, this is a time saver and a money saver for contractors and carpenters everywhere. There is no risk of ruining a piece of material in the processing portion of the job. Therefore there is no need to run out and buy replacement material.

MDF material can also be painted to match paint, stain and other texturing/colorizing work easily. The surface is porous enough to accept paint or stain or even flat primers if the need arises. This makes it a pretty much universal material that is useful in any application or job requirement.

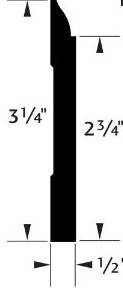

MDF baseboard material is available in a variety of thicknesses and widths. This variety of sizes makes it very easy to find for whatever needs you may have. Whether you need a low profile baseboard or a more prominent showing, this baseboard is available in widths from 3 ¼ wide to as much as 8 wide. Thicknesses can range from 15mm to ¾ in thickness. As you can see, the choices are many, so you can find the right baseboard for your customers requirement.

Another nice feature of this baseboard material is that it can be mitered at the corners for a nice, tight corner fit. When you can make the corners look seamless, the end result is a more professional looking job. Since MDF baseboards come already formed, routed and decorated, all you need to do is cut to length and fit to the application. Nail it in place with a series of low profile finishing nails and the job is complete in a hurry.

As a carpenter, you will love the flexibility of MDF baseboard material. Finishing the job has never been easier.

Return From MDF Baseboard page to Home - Finishcarpentryhelp.com